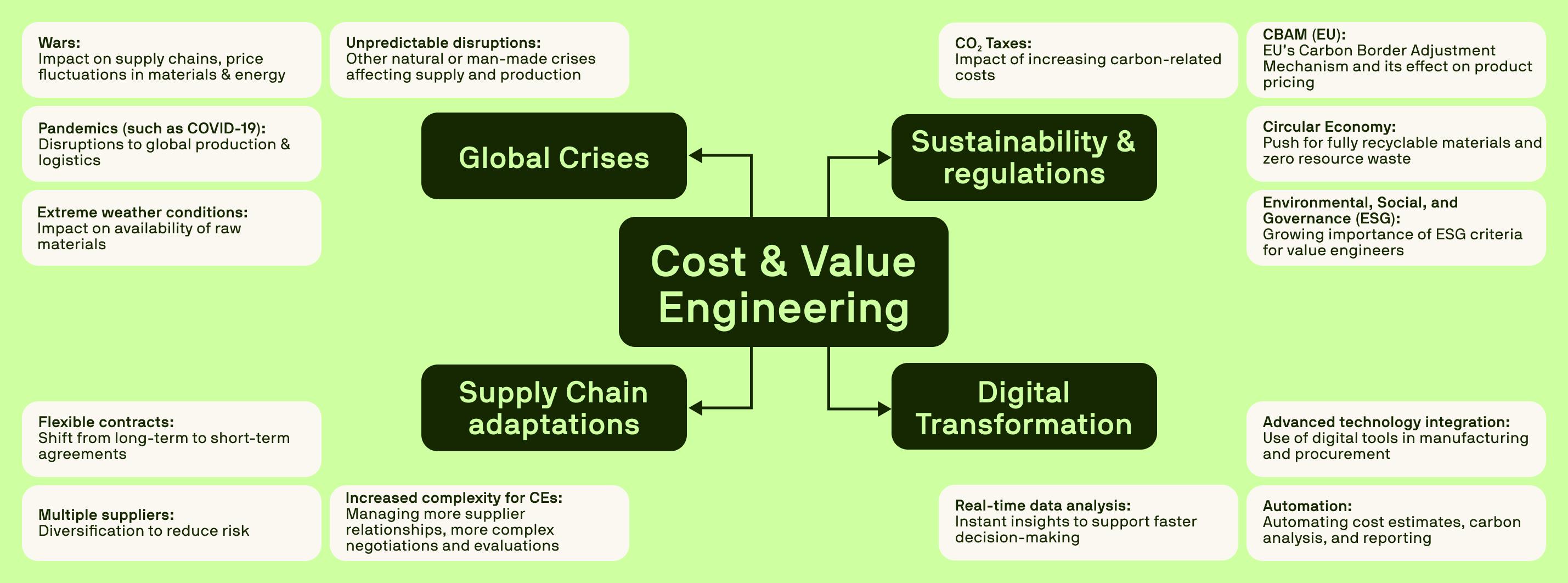

Let’s talk about man-made or natural disasters and crises like wars, COVID-19, heavy rain, storms, and flooding, just to mention a few of them, that caused and will cause huge disruptions in the global supply chain and often lead to material and energy price fluctuations, delays or unavailability of critical components.

Together with consumer demand for customized products, it led to new sourcing strategies away from long contracts with one or few suppliers to short-term contracts with many suppliers to make the supply chain resilient to mitigate the impact of unforeseen events. You can imagine the struggles cost engineers might have to analyze and negotiate with more suppliers or customers more often.

And of course, no one in the manufacturing industry can pass the fear or uncertainty of sustainability and environmental regulations like the Carbon Border Adjustment Mechanism (CBAM) in the European Union or CO₂ taxes on products, which will lead to higher product costs when the companies cannot reduce the carbon footprint. These regulations are designed to reduce carbon emissions and promote sustainable practices in industries.